Ensuring the quality and purity of

PCR recycled polyamide (PA) granules during the recycling process involves a combination of careful procedures, advanced technologies, and quality control measures. Here are key steps commonly taken to maintain the quality and purity of recycled polyamide granules:

Feedstock Sorting and Cleaning:

The recycling process often starts with the collection and sorting of post-consumer or post-industrial plastic waste. Sorting is crucial to remove contaminants and separate different types of plastics. Cleaning involves the removal of non-plastic materials, such as labels, adhesives, and residues.

Material Identification:

Advanced sorting technologies, including near-infrared (NIR) spectroscopy and optical sorting systems, are employed to accurately identify and separate polyamide materials from other plastics during the sorting phase.

Shredding and Size Reduction:

The collected polyamide waste is typically shredded or granulated into smaller pieces to facilitate further processing. Size reduction is essential for improving the efficiency of subsequent steps in the recycling process.

Washing and Degreasing:

The shredded polyamide material undergoes thorough washing to remove remaining contaminants, dirt, and any residual substances. Degreasing processes may also be employed to eliminate oils or lubricants present in the original waste.

Chemical Processing:

Various chemical processes, such as depolymerization or hydrolysis, may be used to break down the polyamide into its molecular components. This can help remove impurities and contaminants while recovering high-quality polymer.

Filtration and Purification:

Filtration techniques, including melt filtration or extruder screens, are employed to remove particles and impurities from the melted polyamide. This step contributes to achieving a purified and uniform material.

Reactive Extrusion or Polymerization:

Some recycling processes involve reactive extrusion or polymerization to regenerate the polyamide polymer. This can result in a material with properties comparable to virgin polyamide.

Additive Removal:

Any additives or colorants present in the original plastic waste are carefully considered during the recycling process. Steps are taken to remove or neutralize these additives to achieve a purified material.

Quality Control Testing:

Rigorous quality control testing is conducted throughout the recycling process. This may include tests for mechanical properties, thermal stability, and chemical composition to ensure the recycled polyamide meets specified standards.

Traceability and Documentation:

Establishing traceability is crucial for ensuring the quality and purity of recycled polyamide granules. Comprehensive documentation of the recycling process, including the source of the material and each processing step, helps verify the material's history and quality.

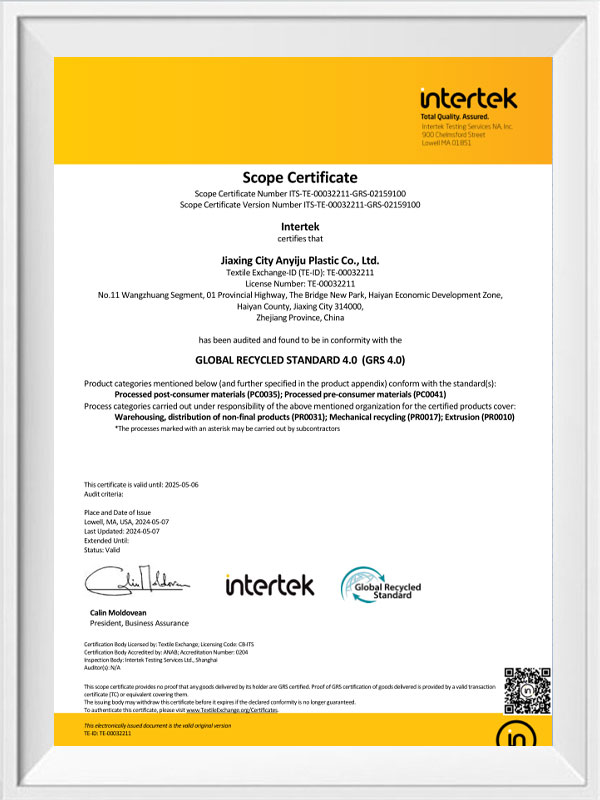

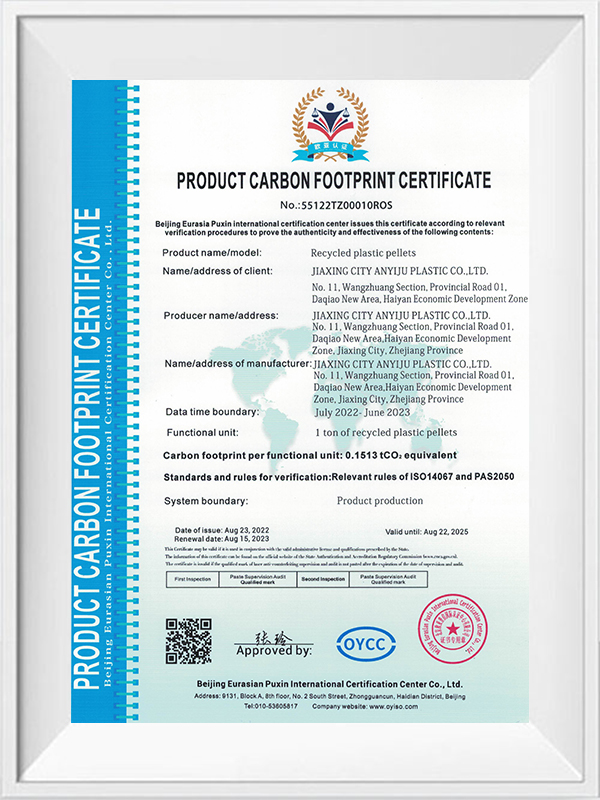

Certifications and Standards:

Manufacturers may seek certifications or adhere to industry standards that verify the recycled polyamide's quality, purity, and compliance with specific environmental criteria.

By implementing these steps and employing advanced technologies, the recycling industry aims to produce high-quality recycled polyamide granules with properties comparable to virgin material, while simultaneously reducing the environmental impact associated with plastic waste. Manufacturers and recyclers often invest in research and development to continually improve the efficiency and sustainability of the recycling process.

简体中文

简体中文 English

English